Both Tencel and cooling fabric have coolness and comfort function, making them ideal for summer wear and home use. However, there are significant differences in their raw materials, production processes, functions, and prices.

1. Raw Materials and Production Processes

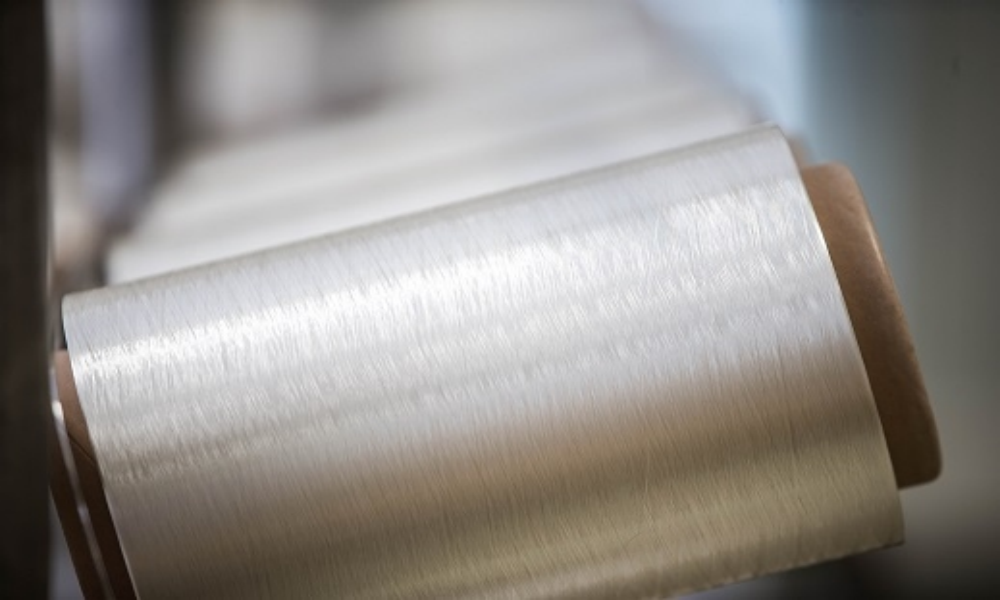

Tencel (TENCEL™): Made from bamboo fiber or wood pulp, undergoing processes such as dissolution, spinning, yarn production, and weaving. Bamboo fiber offers natural antibacterial and odor-resistant properties, while wood pulp is specially processed to create a soft, smooth, and breathable fabric.

Cooling Fabric: Primarily made from polyester fiber, treated with special cool technology. Our cooling products include nylon-cooling and middle PE cooling. Polyester fiber is a synthetic fiber with good wear and wash resistance but may not as good as Tencel in moisture absorption and retention.

2. Functional Differences

Tencel: Known for its moisture absorption and breathability, Tencel has wonderful sweat-releasing capacity, keeping body dry. It also has natural antibacterial and odor-resistant properties, inhibiting bacterial growth and maintaining cleanliness.

Cooling Fabric: With excellent thermal conductivity and moisture wicking properties, cooling fabrics quickly dissipate body heat and transport sweat, providing a lasting cool feeling. They are also durable and withstand frequent washing.

3. Application Scenarios

Tencel: Suitable for home textiles like mattress protectors and duvet covers, as well as summer clothing like T-shirts and dresses, offering a cool and comfortable wearing experience.

3. Application Scenarios

Tencel: Suitable for home textiles like mattress protectors and duvet covers, as well as summer clothing like T-shirts and dresses, offering a cool and comfortable wearing experience.

4. Price

Tencel fabrics are generally pricier due to the complexity of their raw materials and production processes, making them more expensive than cooling fabrics.

Post time: Oct-12-2024